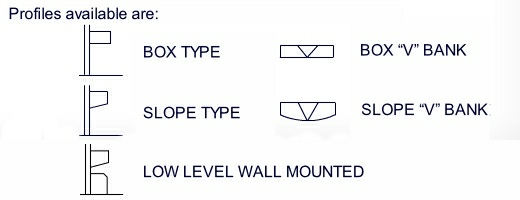

Profiles Available

Naudens Vent Canopies provide efficient ventilation of ovens, steamers, all types of ranges, fryers and griddles.

Features Include

No open drip trays or gutters, free air flow design, fitted as standard with Stainless Steel Naudens clean baffle type grease filters.

Options Include

Integrated make-up-air, built in lights, fire dampers and the choice of 304 Stainless Steel, 430 Stainless Steel or Galvanised Steel construction.

Canopies are complete with welded corner brackets for either island mounting or wall mounting.

Naudens Island Make up Air Canopy

Overhead type canopy (box type). Ceiling mounted with make-up-air facility. For all types of cooking equipment.

Features

- All Stainless Steel construction.

- High efficiency self-draining centrifugal baffle type grease filters.

- Integral make-up-air plenum with internal slot discharge into the canopy.

- Ease of installation, cleaning and servicing.

- Available in single lengths from 1000 millimetres to 5000 millimetres in 100 millimetre increments.

- Flexible options and modifications.

Application

The model is an island type extract or make-up-air canopy for use over medium/heavy-duty commercial cooking equipment where high efficiency grease extraction with internal slot make-up-air distribution is required. This is an overhead canopy suitable for positioning over tall items of equipment, the recommended height to the underside of the canopy being 2 metres minimum and 2.1 metres maximum.

Consultant Specification

Kitchen ventilation canopy shall be an island type box make-up-air complete with full length……….. Stainless Steel baffle type grease filters. The canopy shall be welded construction, with a 50 by 25 perimeter condense channel. All joints and seams shall be welded and/or liquid tight. Removable Stainless Steel grease collecting drawers shall be provided within the apron of the filter housing. A full length , integral, fully insulated, make-up-air plenum shall be incorporated inside each front face of the canopy parallel to the grease filters, each with an internal slot discharge with adjustable baffle plate. Hanging brackets shall be provided on the roof of the canopy.

Modifications and Options

- Volume control dampers in duct spigot.

- OFFSET SPIGOT – Duct spigot can be offset (left or right of centre line).

- DIMENSIONS – height, length and depth can be altered as required – consult factory.

- LIGHTS – Recessed vapour-proof fluorescent fittings to give approximately 500 Lux a work surface height.

- Surface fire suppression.

- Services distribution units.

- Pollution control.

Recommendation

The island type box make-up-air incorporates a make-up-air facility which, when connected to a ductwork system, will introduce un-tempered make-up-air, at a low velocity, directory into the canopy. This serves two purposes:

- It will allow raw, fresh air to be utilised which would not require heating as it would not come into contact with kitchen staff.

- It has the effect of dropping the temperature of the extracted air, thereby making the centrifugal grease eliminators more efficient.

Our tests indicate that the maximum make-up-air flow rate which should be introduced directly in the canopy, in this manner, is 50% of the extract flow rate. We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn surrounding areas and the kitchen will be maintained under negative pressure.

Naudens Slope Style Canopy

Slope type canopy for counter top cooking equipment.

Features

- All Stainless Steel construction.

- High efficiency self-draining centrifugal baffle type grease filters.]

- Ease of installation, cleaning and servicing.

- Available in single lengths from 1000 millimetres to 5000 millimetres in 100 millimetre increments.

- Flexible options and modifications.

- Access panel for plenum cleaning.

Application

The model is slope type extract canopy for use over medium/heavy-duty commercial cooking equipment where high-efficiency grease extraction is required. This type of canopy is commonly used as part of a server where the facility to pass the plated food across to the customer, or waitress, is required. It is only suitable for use over low height cooking equipment and is extremely efficient, as the point of extraction is in close proximity to cooking surface. Please specify whether duct discharge should be up-flow, down-flow or horizontal.

Consultant Specification

Kitchen extract canopy shall be a Naudens slope type complete with full length, baffle type grease filters and grease collecting drawers. Specify if the duct discharge is to be up-flow, down-flow or horizontal.

Modifications and Options

- Stainless Steel supports for tray slide/facia panels.

- Surface fire suppression.

- Pollution control.

- Volume control dampers.

- Volume control dampers.

Recommendation

We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen or servery will be made maintained under negative pressure.

Naudens Condensate Canopy Type

Overhead type canopy (bow type) for condense type extraction.

Features

- All Stainless Steel construction from 304 or 430 grade satin finish sheet.

- All welded construction.

- Ease of installation, cleaning and servicing.

- Available in single lengths from 1000 millimeters to 5000 millimeters in 100 millimeter increments.

Application

Developed for use over dish washing machines, pot wash machines, water boilers, etc. where grease filtration is not essential, but heat and steam extraction is desirable.

Consultant Specification

Kitchen extract canopy shall be a Naudens Box Condensate Model. All welded construction with a 50 x 25 perimeter condense channel. Hanging brackets shall provide in each corner of the roof panel.

Modifications and Options

- Make-up-air through front face diffusers (tempered) or internal slot (un-tempered).

- Fluorescent light fittings to give approximately 500 Lux at work surface height.

- Condense drain outlet (if appropriate).

Recommendations

We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen will be maintained under negative pressure.

Naudens Box Type Canopy

Overhead type canopy – ceiling or wall mounted, for all types of cooking equipment. With integral, internal make-up-air.

Feature

- All Stainless Steel construction.

- High efficiency self-draining centrifugal baffle type grease filters.

- Removable Stainless Steel grease collecting drawers.

- Ease of installation, cleaning and servicing.

- Available in lengths 1000 millimetres to 5000 millimetres in 100 millimetre increments – consult factory if over 3000 millimetres.

- Flexible options and modifications.

Application

Developed for use over medium/heavy-duty commercial cooking equipment where high efficiency grease extractions are required. Normally wall mounted but can be island mounted over a single line of cooking equipment, the recommended height to the underside of the canopy being 2 metres minimum and 2.1 metres maximum.

Consultant Specification

Kitchen ventilation canopy shall be a box complete with full length Stainless Steel Centrex Stainless Steel baffle type grease filters. All welded construction, with a 50 x 25 perimeter condense channel. All joints and seams shall be welded and/or liquid tight. Removable Stainless Steel grease collecting drawers shall be provided within the apron of the filter housing. A full length, integral fully insulated, make-up-air plenum shall be incorporated inside the front face of the canopy, with an internal slot discharge with adjustable baffle plate. Hanging brackets shall be provided on the roof of the canopy.

Modifications and Options

- OFFSET SPIGOT – Duct spigot can be offset (left or right of centre line).

- REAR DUCT – Rear duct spigot take off.

- LIGHTS – Recessed vapour-proof fluorescent fittings to give approximately 500 Lux at work surface height.

- Make-up-air through front face diffuser.

- Surface fire suppression.

- Services distribution units.

- Pollution control.

Recommendation

The Naudens box incorporates a make-up-air facility, which, when connected to a ductwork system, will introduce un-tempered make-up-air, at a low velocity, directly into the canopy. This serves two purposes:

1. It will allow raw, fresh air to be utilised which would not require heating as it would not come into contact with the kitchen staff.

2. It has the effect of dropping the temperature of the extracted air, thereby making the centrifugal grease eliminators more efficient.

Our tests indicate that the maximum make-up-air flow rate which should be introduced directly in the canopy, in this manner, is 50% of the extract flow rate. We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen will be maintained under negative pressure.

Naudens Low Level Type Canopy

Low level type canopy for wall mounting over bench height cooking equipment, with front face make-up-air facility.

Features

- All Stainless Steel construction.

- High efficiency self-draining centrifugal baffle type grease filters.

- Flexible options and modifications.

- Ease of installation, cleaning and servicing.

- Available in single lengths from 1000 millimetres to 5000 millimetres in 100 millimetre increments.

- Three-sided Stainless Steel duct – cladding.

Application

The model is a low level wall type extract canopy for use over medium/heavy-duty commercial cooking equipment where high efficiency grease extraction is required. As a low level canopy this type is suitable for use over low height cooking equipment such as ranges, fryers, griddles, etc., and is widely accepted as being one of the most efficient types of canopy, as the point of extract is close to the cooking surface.

Consultant Specification

Kitchen extract canopy shall be a Naudens Low Level Wall Make-Up-Air complete with full length Naudens Centrex Stainless Steel baffle type grease filters.All joints and seams shall be welded and/ or liquid tight. Removable Stainless Steel grease collecting drawers shall be provided within the apron of the filter housing. Canopy to be fixed to rear wall through opening in filter housing. Integrated insulated make-up-air plenum is located at the front of the canopy. Make-up-air is discharged through perforated Stainless Steel panels.

Modification and Options

- OFFSET SPIGOT – Duct spigot can be offset (left or right of centre line).

- REAR DUCT – Rear duct spigot take off – consult factory.

- DIMENSIONS – height, length and depth can be altered as required.

- Make-up-air through front face diffuser.

- Volume control dampers.

- Surface fire suppression.

- Pollution control.

- STAINLESS STEEL FINISHED BACK – Where exposed, for island applications.

Recommendation

We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen will be maintained under negative pressure.

Box Make-Up-Air Type

Overhead type canopy (box type). Ceiling mounted with make-up-air facility for all types of cooking equipment.

Features

- All Stainless Steel construction.

- High efficiency self-draining centrifugal baffle type grease filters.

- Integral make-up-air plenum with Prefair diffuser panels.

- Available in lengths from 1000 millimetres to 3000 millimetres in 100 millimetre increments.

- Flexible options and modifications.

Application

Developed for use over medium/heavy-duty commercial cooking equipment where high efficiency grease extractions are required. Normally wall mounted but can be island mounted over a single line of cooking equipment, when a finished back would be provided. This is an overhead canopy suitable for positioning over tall items of cooking equipment, the recommended height to the underside of the canopy being 2 metres minimum and 2.1 metres maximum.

Consultant Specification

Kitchen ventilation canopy shall be a Naudens Model Make-Up-Air complete with full length Vent Master Stainless Steel baffle type grease filters. The canopy shall be constructed from 1.2 millimetre thick grade 304 or 430 satin finish Stainless Steel, all welded construction, with 50 by 25 perimeter condense channel. All joints and seams shall be welded and/or liquid tight. Removable Stainless Steel grease collecting drawers shall be provided within the apron of the filter housing. A full length, integral, fully insulated, make-up-air plenum shall be incorporated inside the front face of the canopy, parallel to the grease filters with removable, Stainless Steel, Prefair, perforated plate diffusers in the outer face. Hanging brackets shall be provided on the roof of the canopy.

Modifications and Options

- Volume control dampers in duct spigot.

- OFFSET SPIGOT – Duct spigot can be offset (left or right of centre line).

- DIMENSIONS – height, length and depth can be altered as required – consult factory.

- LIGHTS – Recessed vapour-proof fluorescent fittings to give approximately 500 Lux a work surface height.

- Surface fire suppression.

- Services distribution units.

- Pollution control.

Recommendation

The make-up-air incorporates a make-up-air facility, which, when connected to a ductwork system, will introduce tempered make-up-air, at a low velocity, into the immediate vicinity of the source of extraction. We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85% of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen will be maintained under negative pressure.

Naudens Ultra Violet Vents

A Breakthrough in Kitchen Ventilation

Air extracted from above commercial cooking equipment contains vaporised cooking oil, water vapour, smoke and entrained fat. Depending on the efficiency of the grease filters into the ventilation canopy, most of these airborne contaminants should be arrested at source and not conveyed, via the ductwork system, to the atmosphere. However, with inefficient grease filters, high temperature exhaust air, poor ventilation systems or a combination of all three, then the result will be:

- Grease lined exhaust ductwork, with a high fire risk and a costly cleaning programme.

- Unacceptably high smoke emissions.

- Unacceptably high odour emissions.

The Naudens UV Vent range of ventilation canopies, especially developed to overcome these problems, incorporates removable High Off Efficiency Stainless Steel cartridge filters.

The use of high efficiency pre filters and harnessing the tried-and-tested Ultra Violet technology, to destroy airborne grease and odours, combined to deliver the most efficient commercial kitchen equipment ever seen.

Ultra Violet (UV) can be produced in three brands, UV-A, UV-B and UV.

UV produced by special high intensity UV light tubes also reacts with the oxygen in the air producing traces of ozone.

After the grease filters have reduced the grease volume, the dirty air containing vaporised cooking oil, water vapour and entrained fats and odours are passed over the UV light tubes. The intense UV lights break down the remaining organic material using a combination of photolysis and ozonolysis, to leave carbon and water vapour as end products.

Naudens UV Vent

Naudens UV Vent

Type:

Construction:

The canopy is of modular construction, all joints and seams are continuously welded and liquid tight. All exposed welds are ground and polished to original finish, internal seams are filled with non-hardening sealer. With the use of high efficiency pre-filters and harnessing, the tried-and-tested Ultra Violet technology destroys airborne grease.

Material

1.2 millimetre grade 304 or 430 Stainless Steel, number 4 stain finish.

Filter

Naudens Stainless Steel vertical S-baffle impingement type manufactured from 430 BA Stainless Steel.

Exhaust Fire Damper

Manufactured from 1.6 millimetre grade 304 Stainless Steel. Fusible link type rated at 280 degrees Fahrenheit. The damper to be accessible from the inside of the kitchen canopy.

Lights

Flush fitting vapour sealed with double fluorescent tubes, to give 500 Lux at the working level.

Specifications Governing the Installation of Hoods or Canopies in Food Handling Premises

The Public Health By-laws of the greater Johannesburg Transitional Metropolitan Council require that where cooking is carried out in any food handling premises a hood or canopy shall be provided over all cooking appliances. The hood must be fitted with an exhaust duct discharging in such a way as to cause a nuisance to the neighbourhood.

The purpose of the whole installation is threefold, it must remove steam and fats from the cooking area to prevent them from dispersing and condensing on the walls and ceiling of the room, it must prevent cooking odours from pervading the rest of the premises, and it must effect ventilation in the room and the removal of excess heat. To do these things effectively, the system must be properly designed, constructed and maintained.

Hoods or canopies conforming to the following shall be regarded as complying with the By-laws:

- The inside edge of the hood shall extend a horizontal distance of not less than 230 millimetres on all open sides beyond the extremities of the cooking appliance(s).

- The lip of the hood shall not be more than 2 metres from the floor.

- The depth of the hood from the lower to the upper edge shall not be at least 600 millimetres.

- The hood shall be served by an exhaust fan of sufficient capacity to ensure either:

- a. An air movement, measured at the inlet of the hood, i.e. in the plane of its greatest area of at least 30.5 metres per minute. Or…

- b. A ventilation rate in the room in which the hood is installed of at least 20 air changes per hour, whichever is cheaper.

- NOTE: (a.) is suitable for small hoods in relatively large rooms, while (b.) is suitable for larger hoods in relatively small rooms.

UV Vent

UV Vent

- Breakthrough technology.

- First true innovation in kitchen ventilation in years.

- Market leader in kitchen ventilation technology.

How does UV Vent Work?

- UV-C lamps break down the entrained organic compounds in the kitchen exhaust by Photolysis and Ozonolysis, eliminating grease and odour.

- The end products of the reactions with the organic compounds are Carbon Dioxide (CO2) and water vapour (H2O).

- Ozone (O3) is produced by the lamps and carried down the ductwork. A cold combustion process occurs, destroying any other organic material, leaving clean ducts and reducing cooking odours.

What are the Benefits of UV Vent?

- NO GREASE in the exhaust ducts.

- No accumulation of grease on exhaust fan or building roof. Both the fan and roof last longer.

- Greatly extended filter life when used in conjunction with an Ecology Unit (reduced operating cost.).

- Reduced odour at fan discharge.

- Constant pressure drop (no grease accumulation to restrict airflow.) decrease CFM’s and cause capture and containment problems.

What are the Cost Implications?

- UV Vent hood systems are similar in first to Cold Water Mist/ Hot Water Wash hood systems.

- There are capital cost savings due to the absence of:

- Water piping.

- Drains.

- Grease traps.

- Hot water supply (sizing and usage.).

- Detergent.

- Wash Panel.

- Additional cost savings are realized with little or no duct cleaning.

How is it Maintained?

- Maintenance of the cartridges and particle separations is carried out by the kitchen staff during their routine cleaning program (run through the dishwasher or cleaned in pot sink.).

- Cleaning of the lamps is carried out trained, factory approved service technicians on a quarterly basis (depending on the type and volume of cooking.).

- Lamp life expectancy is approximately 8000 hours or 1.5 to 2 years in a typical food service facility.

Is UV Vent Safe?

- YES – Interlocks and security features have been built in to the UV Vent system to turn off the UV lamps if access doors are open or any filters removed.

- All risk of contact with the lit UV lamps has been eliminated.

- A control panel operates and monitors the system, also providing a connection to the fire suppression system.

Naudens Make-Up-Air Condensate Type

Overhead type canopy (box type) with front face make-up-air facility, for condense type extraction.

Features

- All Stainless Steel construction from grade 304 or 430 satin finish sheet.

- All welded construction.

- An aluminium egg crate type extract grill with opposed blade damper in each extract spigot.

- Integral make-up-air plenum with removable Perfair diffuser panels.

- Ease of installation, cleaning and servicing.

- Available in lengths from 1000 millimetres to 3000 millimetres in 100 millimetre increments.

- Flexible options and modifications.

Application

Developed for use over dishwashing machines, pot wash machines, water boilers, etc., where grease filtration is not required, but heat and steam extraction is desirable, and close proximity make-up-air is required.

Consultant Specification

Kitchen ventilation canopy shall be a Naudens Make-Up-Air Condensate Canopy. All welded construction, with a 50 by 25 perimeter condense channel. The extract spigot shall incorporate an aluminium egg crate type extract grill with opposed blade damper and mez type flange. An integral make-up-air facility is to be provided by use of full length, fully insulated plenum, and removable Stainless Steel perfair perforated plate diffuser in the front face.

Modifications and Options

- Stainless Steel finished back for island mounting.

- Facility for un-tempered air to be introduced via an internal slot.

- Fluorescent lights to give approximately 50Lux at work surface height.

- Condense drain outlet (if appropriate).

Recommendation

We strongly recommend that make-up-air is introduced directly into the areas where extract canopies are sited and, generally, this should amount to between 75 to 85& of the extract flow rate. The balance will then be drawn from surrounding areas and the kitchen will be maintained under negative pressure.